Adding product to the cart!

Added to the cart!

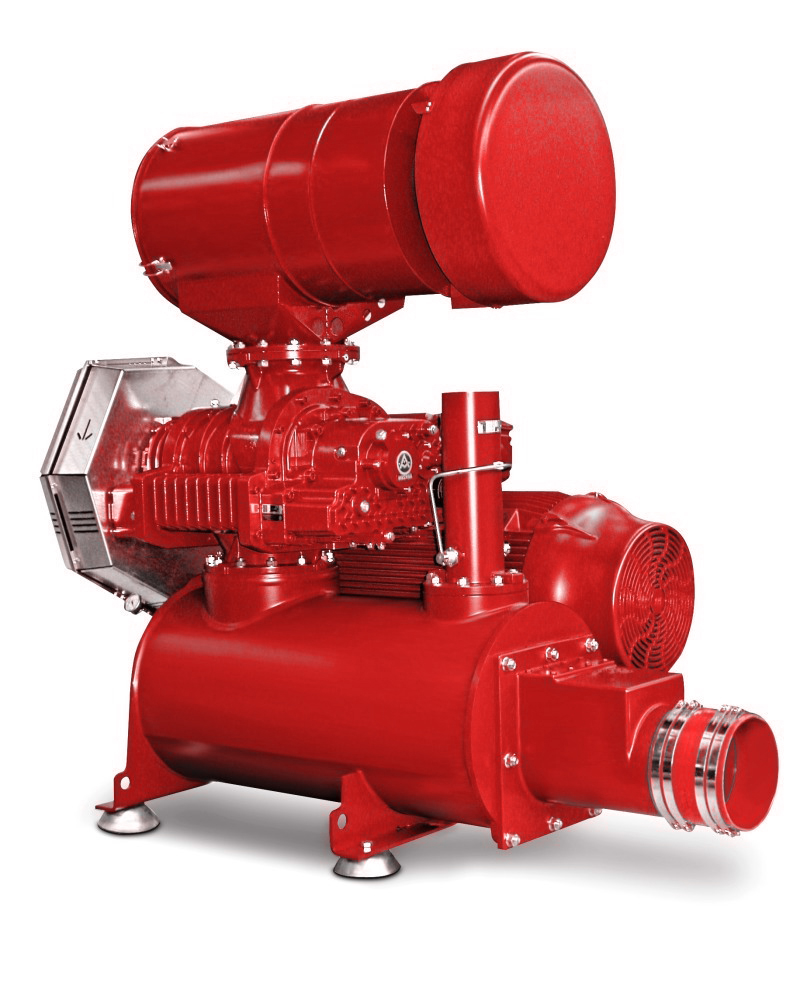

Lobe Compressors

Lobe compressors are a type of positive displacement rotary compressor that uses two or more lobes to trap and compress a gas. The lobes mesh together inside a casing, creating a series of chambers that increase in pressure as they rotate.

Description

How They Work

- Lobe Rotation: Two or more lobes rotate within a casing. The lobes are shaped to mesh together without touching, creating a series of chambers.

- Suction: As the lobes rotate, they create a vacuum in the chamber, causing the gas to be drawn into the compressor.

- Compression: The gas is trapped within the chambers as the lobes rotate. As the chambers decrease in volume, the pressure of the gas increases.

- Discharge: The compressed gas is discharged from the compressor.

Advantages of Lobe Compressors

- Continuous flow: Provides a continuous, pulsation-free flow of compressed gas.

- Quiet operation: Generally quieter than other types of positive displacement compressors.

- Gentle compression: The lobes do not come into contact with the gas, reducing the risk of contamination or wear.

- Wide range of applications: Suitable for a variety of gases and operating conditions.

Applications

- Industrial processes: Used for conveying powders, granules, and slurries.

- Food and beverage industry: Used in packaging and processing applications.

- Pharmaceutical industry: Used for handling sensitive materials.

- Vacuum systems: Used as vacuum pumps.

Reviews

There are no reviews yet.