Adding product to the cart!

Added to the cart!

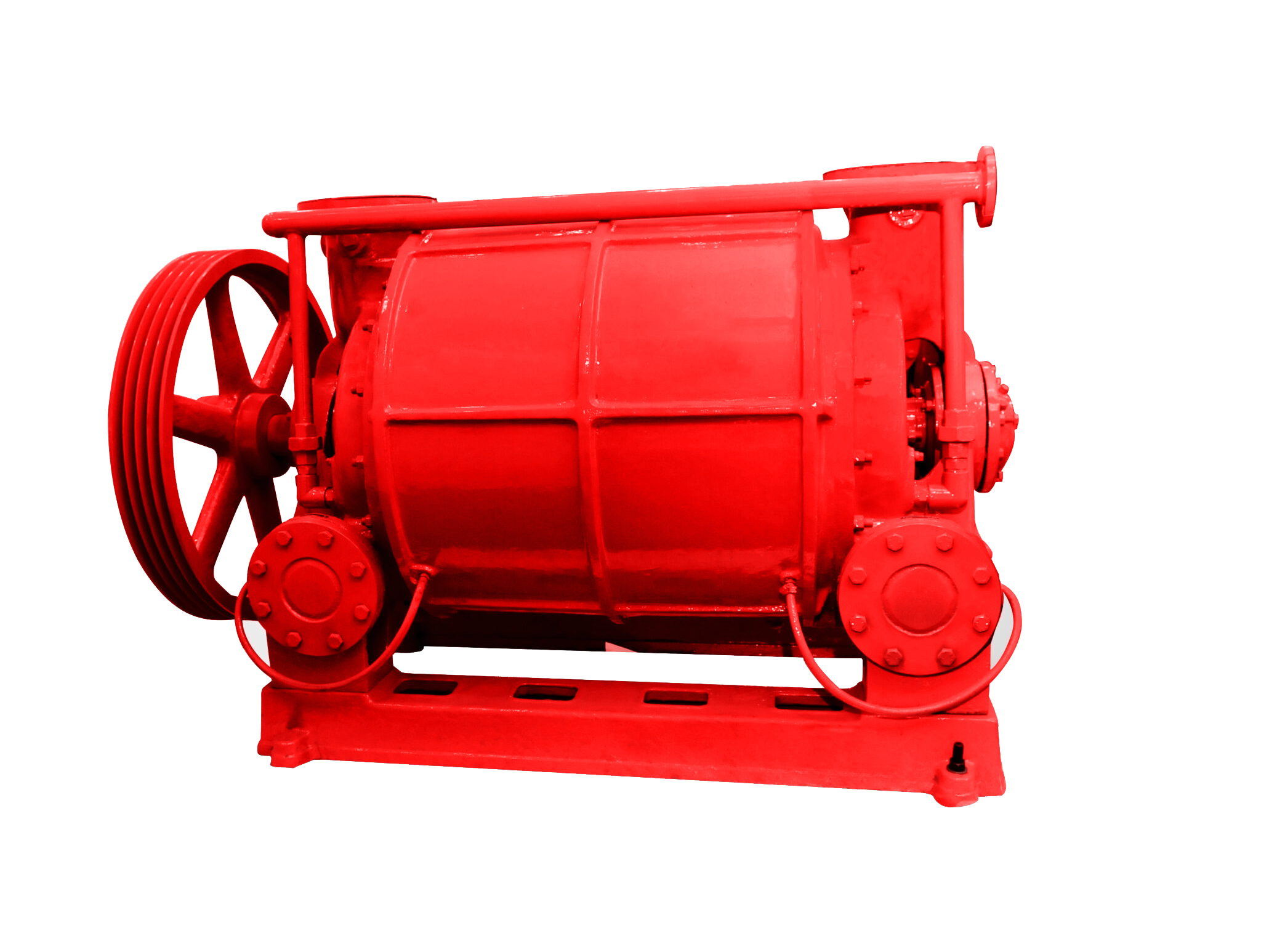

Liquid Ring Compressors

Liquid ring compressors are a type of positive displacement rotary compressor that uses a rotating impeller to create liquid rings which compress the gas. The liquid, usually water, forms a seal between the impeller and the casing, and also acts as a cooling medium.

Description

How They Work

- Impeller Rotation: The impeller rotates within a casing, creating cavities between the impeller vanes and the casing.

- Liquid Filling: The casing is partially filled with a liquid, typically water. As the impeller rotates, the liquid is flung outward by centrifugal force, forming a continuous liquid ring around the inner periphery of the casing.

- Gas Compression: Gas is introduced into the cavities between the impeller vanes and the liquid ring. As the impeller rotates, the volume of these cavities decreases, compressing the gas.

- Discharge: The compressed gas is discharged through an outlet port.

Advantages of Liquid Ring Compressors

- Handles moist or dirty gases: The liquid acts as a sealant and helps to prevent damage from contaminants.

- Can compress large volumes of gas: Capable of handling high flow rates.

- Gentle compression: The liquid cushion reduces the wear and tear on the compressor components.

- Can handle a wide range of pressures: Suitable for both low and high-pressure applications.

Applications

- Vacuum systems: Used as vacuum pumps in various industries.

- Chemical processing: Used for compressing corrosive or abrasive gases.

- Wastewater treatment: Used for compressing biogas.

- Petrochemical industry: Used for handling hydrocarbons and other process gases.

Reviews

There are no reviews yet.