Adding product to the cart!

Added to the cart!

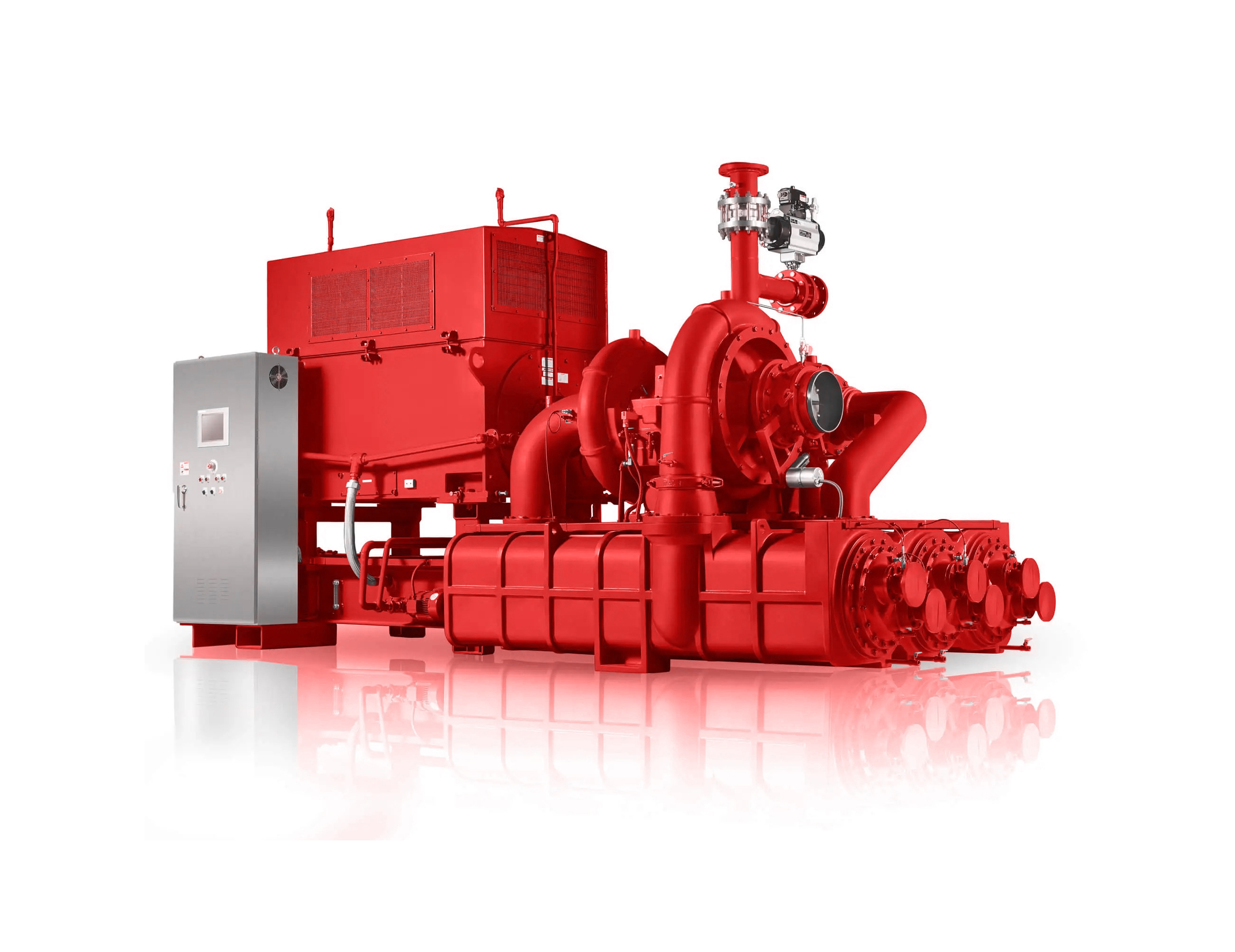

Centrifugal Compressors

Centrifugal compressors are a type of dynamic compressor that increases the pressure of a fluid (typically a gas) by converting kinetic energy into potential energy. They are widely used in various industries, including the petroleum, chemical, and power generation sectors.

Description

How They Work

-

- Impeller: At the heart of a centrifugal compressor is the impeller, a rotating disk with curved blades. As the impeller spins, it draws in the fluid at its center.

- Acceleration: The blades accelerate the fluid, increasing its velocity and kinetic energy.

- Diffusion: The fluid then enters a diffuser section, where the passage area increases. As the fluid moves through the diffuser, its velocity decreases and its pressure increases due to the principle of conservation of energy.

- Discharge: The pressurized fluid is discharged from the diffuser.

Advantages of Centrifugal Compressors

- High flow rates: Capable of handling large volumes of fluid.

- Relatively simple design: Fewer moving parts compared to other compressor types.

- Continuous operation: Can operate continuously for extended periods.

- Smooth operation: Generally produce less vibration and noise.

- Wide range of applications: Suitable for various fluids and operating conditions.

Applications

-

-

- Petroleum industry: Compressing natural gas and refinery gases.

- Chemical industry: Compressing process gases.

- Power generation: Used in gas turbines for power generation.

- Refrigeration: Compressing refrigerants in large-scale refrigeration systems.

- Air conditioning: Providing compressed air for HVAC systems.

Reviews

There are no reviews yet.