Adding product to the cart!

Added to the cart!

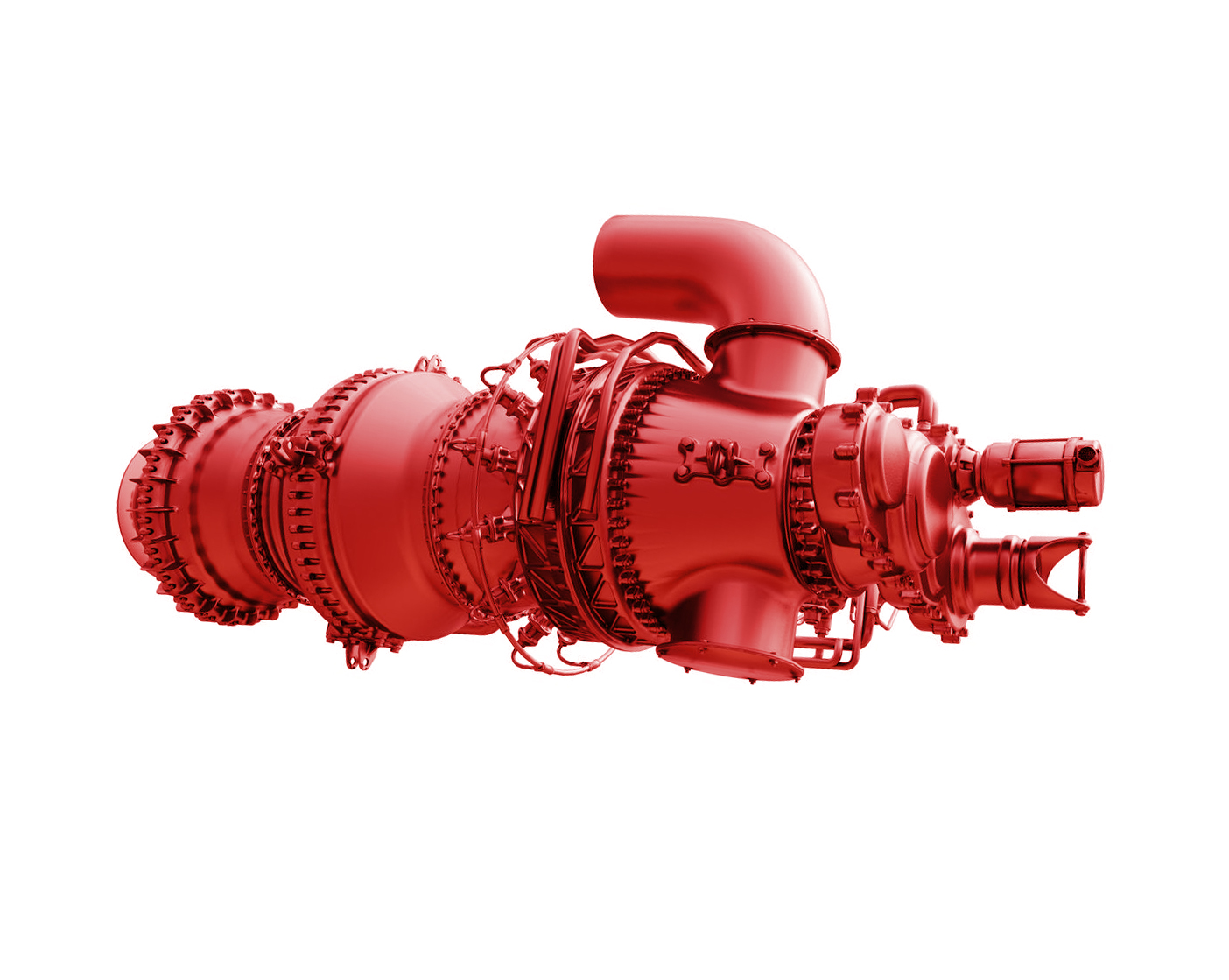

Axial Compressors

Axial compressors are a type of dynamic compressor where the fluid flow is primarily parallel to the axis of rotation. They are commonly used in gas turbines, jet engines, and industrial applications where high flow rates and moderate pressure ratios are required.

Description

How They Work

-

- Rotor and Stator Blades: An axial compressor consists of alternating rows of rotating blades (rotor) and stationary blades (stator).

- Acceleration: As the fluid enters the compressor, it encounters the rotating blades, which impart energy to the fluid, increasing its velocity.

- Diffusion: The fluid then passes through the stator blades, which convert the kinetic energy into pressure. This process is repeated in multiple stages to achieve the desired pressure ratio.

Advantages of Axial Compressors

- High flow rates: Axial compressors can handle very high flow rates.

- High efficiency: They typically have high efficiencies, especially at high flow rates.

- Compact design: They can be designed to be very compact for their capacity.

- Continuous operation: Axial compressors can operate continuously for extended periods.

Applications

- Gas turbines: Used in both land-based and aircraft gas turbines.

- Jet engines: A core component of jet engines.

- Industrial processes: Used in various industrial processes, such as boosting the pressure of natural gas.

Reviews

There are no reviews yet.