Adding product to the cart!

Added to the cart!

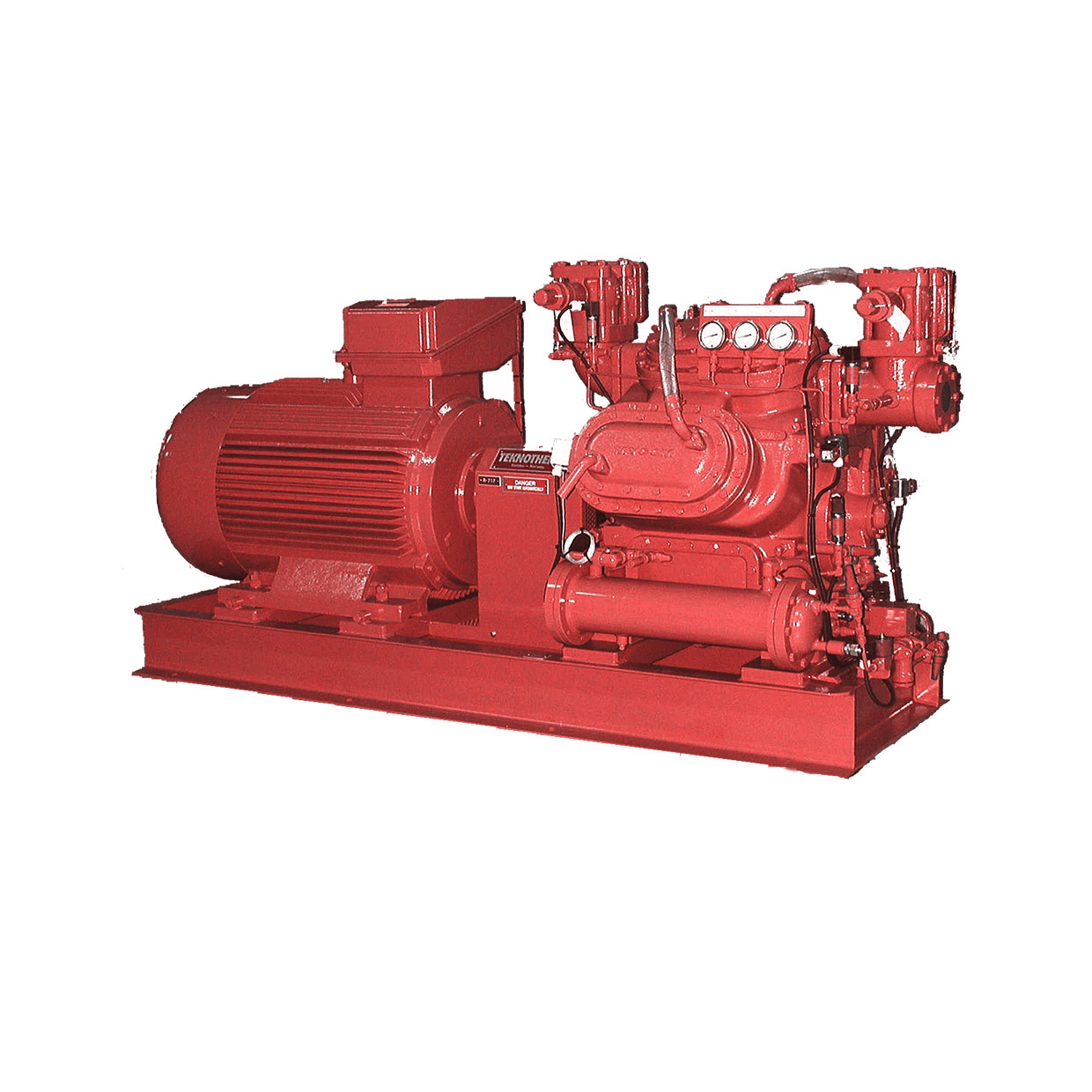

Reciprocating Compressors

Reciprocating compressors are a type of positive displacement compressor that uses a piston moving back and forth in a cylinder to compress a gas. The piston is driven by a crankshaft, which converts rotary motion into reciprocating motion.

Description

How They Work

- Suction Stroke: The piston moves away from the cylinder head, creating a vacuum in the cylinder. This vacuum draws the gas into the cylinder through an inlet valve.

- Compression Stroke: The piston moves towards the cylinder head, compressing the gas trapped in the cylinder.

- Discharge: When the piston reaches the end of its stroke, the compressed gas is forced out of the cylinder through an outlet valve.

Advantages of Reciprocating Compressors

- High pressure ratios: Can achieve very high pressure ratios in a single stage.

- Versatile: Can handle a wide range of gases and operating conditions.

- Robust construction: Typically very robust and reliable.

Applications

- Industrial processes: Used for a wide range of industrial applications, such as refrigeration, air conditioning, and natural gas compression.

- Automotive industry: Used in air compressors for braking systems and suspension systems.

- Oil and gas industry: Used for boosting the pressure of natural gas.

Reviews

There are no reviews yet.